ElectraCOOL™ Thermoelectric Module Reliability

Advanced Thermoelectric has always supplied thermoelectric modules you can depend on.

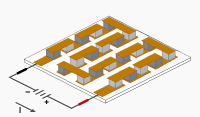

Thermoelectric modules consist of TE material or "dice" arranged between substrates. Conventional modules are made by soldering TE dice to copper pads bonded to alumina ceramics (DBC substrates). A standard 40mm square, 127-couple module has 254 dice. Each of the dice have solder joints to both the hot and cold-side substrates, for a total of 508 joints. The weakening of a single solder joint will cause a degradation in performance, typically leading to an electrical short. When power is applied to the TE material one side of the module gets cold and the other gets hot.

Approximately 90% of our customers use our thermoelectric modules to hold something at a constant temperature. Modules used as “coolers” or “warmers,” will provide many years of highly reliable service. (Modules that operate at, or below, the dew-point should have an edge seal to keep water from entering the module that could cause a short. We prefer the properties of epoxy but also offer silicone RTV.

In some applications, TE modules may be required to provide different temperatures, often involving a switch in polarity to change from cooling to warming. This is known as "thermal cycling."

Hot things expand while cold things contract. A change in polarity causes the contracting cold-side substrate to begin slight expansion and vice versa on the hot-side. Over time, this can weaken solder joints. The magnitude of this stress depends on a variety of factors that include set-points, ramp-rates the rapidity of the polarity switch and magnitude of power applied during the change.

Set-point temperatures are not nearly as significant as the ramp-rate and time to switch polarity but, very hot or cold surfaces will naturally see the greatest expansion and contraction. The shorter the ramp-rate, the greater the thermally induced stress however, the major factor affecting the reliably of modules, in cycling applications, is making immediate (and full power) switches in polarity. It’s a good idea to plan a little rest, and thermal softening, before switching polarity.

To address the needs of customers with thermal cycling applications, we have integrated into our product-line TE modules with unique construction and know-how, that are particularly well suited in such challenging environments.

The thinking behind the development of these ‘cycling’ modules was to reduce the surface area impacted by the shifting expansion and contraction of the ceramic substrates.

Our thermal cycling modules don’t use the typical Direct Bond Copper, or DBC ceramics. Instead, bare ceramics with individual copper pads, arranged similarly to those on a DBC ceramic, are attached with a special adhesive, or glue, to the hot-side ceramic. This substantially reduces the affected surface area from the foot-print of the ceramic substrate to that of the copper pad. Additionally the adhesives used have a degree of flexibility, or give, that further enhance reliability. It’s a patented process and it works.

If your company uses TE modules in a cycling application we encourage you to contact us to discuss your requirements.

sales@electracool.com or in North America our toll free phone number is: 1 (866) 665-5434.

Our commitment to delivering thermoelectric modules that will perform as advertised requires rigorous Quality Control standards, testing and routine inspection.

Reliability Test Standards

| Test Category | Test Name | Test Condition | Criterion |

|---|---|---|---|

| Life Tests | Continuous Operation Test | 1,000 Hours | Internal Resistance Value Changes Less Than ±10% Visual Damage Others |

| ON-OFF Operation Test | 5,000 Cycles | ||

| Polarity Switching Test | 15,000 Cycles | ||

| Environmental Tests | High Temperature Storage Test | 90 °C 1,000 Hours | |

| Low Temperature Storage Test | -40 °C 1,000 Hours | ||

| Thermal Shock Test | 0 °C ~ 100 °C 10 Cycles | ||

| Temperature-Humidity Cycling Test | 10 cycles | ||

| Mechanical Shock Test | Freefall From A Height of 25cm 3 Times | ||

| Vibration Test | 100~2,000Hz 4 Cycles Each In 3 Directions | ||

| Lead Pulling Test | Pulling Strength 10N, 20N, 30N Maintained For 10 Seconds |

Volume customers are welcome to inquire about additional QC, burn-in, sorting or other services.

Related Links:

sales@electracool.com

Toll free in North America: 1 866.665.5434

International: 603.888.2467